VOC Condenser

Unmanned tank cleaning step process

Transfer operation

Empty the storage tank to be cleaned (Trough A). When the storage tank to be cleaned is emptied by the process pump, the remaining oil at the bottom of the tank will be transported by piping with external equipment or vacuum pumped and transported to Tank B for recycling. For pumped storage and transportation For oil residue recovery, chemical vacuum pumping and escape prevention tank trucks are used to efficiently pump and store residual oil (the chemical vacuum pumping and escape prevention tank truck equipment adopts a green gate design, and the VOC escape prevention function reaches more than 99%).

Top water and 3D cleaning operations

Float and remove top water for unevenness and depression in the oil tank and dead corners of the wall. Wastewater is generated when the top water is completed, which is collected and discharged by chemical vacuum pumping and discharged by three-phase high-speed separation equipment for treatment. Oily oil and water are purified and recovered using multi-stage cyclone and centrifugal high-speed separation. If the owner passes the acceptance, the process will be provided for production use, and the wastewater discharge process will be clarified at the wastewater treatment station. , second-stage treatment of concentrated oil pollution, three-phase high-speed separation and dehydration, drying of mud cake, using 50-gallon iron drum device, the owner accepts that the moisture content of the mud cake is qualified, and the owner indicates the location for storage.

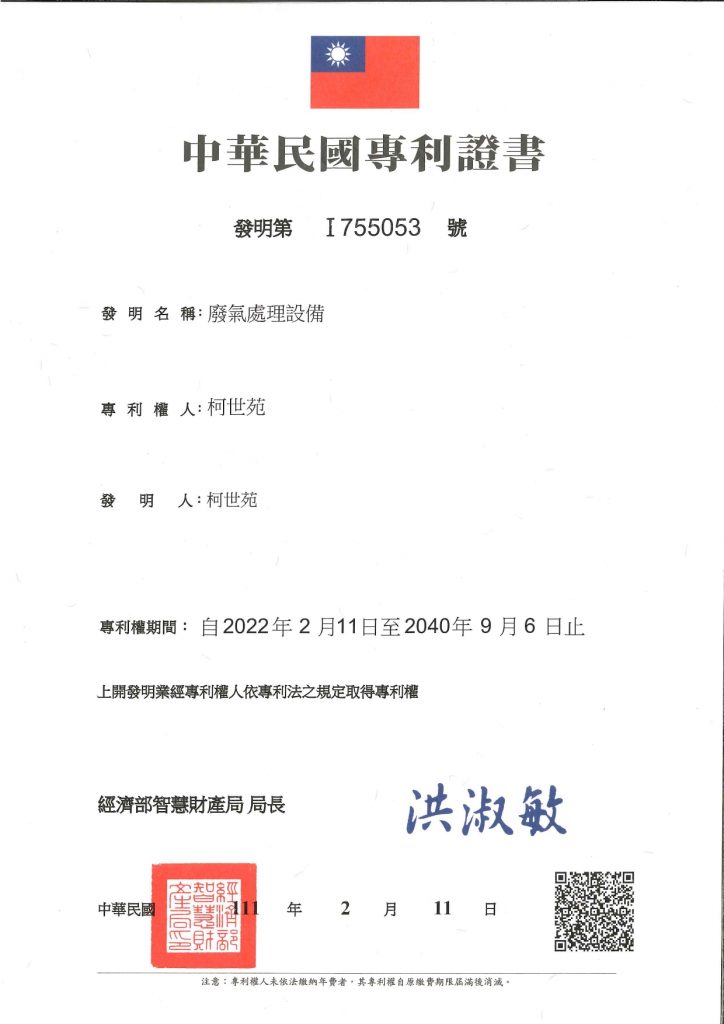

VOC Gas Displacement

The cleaning tank performs gas replacement in accordance with regulations for VOC and adopts condensation internal circulation recovery treatment. The VOC emission reduction rate reaches more than 90%. The storage tank is opened in accordance with Formosa Plastics regulations. The VOC TVA-1000 detection value in the tank is below 1000PPM.

Groove cleaning

Start cleaning the storage tank. Use chemical anti-escaping pumping and storage equipment to clean the oil sludge, rust, and sandy sludge in the tank. Use vacuum mechanical cleaning in the tank. Use high-pressure cleaning to clean the bottom and walls of the tank. Once the storage tank is cleaned and accepted, it will be handed over to the owner for use. , Centrifugal treatment of wastewater in the cleaning tank, two- and three-phase solid-liquid separation treatment.

Transfer tank oil treatment, oil-water separation

Multi-stage cyclone three-phase separation → A purified oil product B clarified waste water C concentrated sludge; the concentrated sludge in the transfer tank oil treatment adopts two-phase centrifugal dehydration and drying, and is installed in a 50-gallon barrel.

Wastewater and oil pollution treatment

The first stage: waste oil sludge water buffer tank, preheating tank; the second stage: multi-stage cyclone sludge concentration equipment → concentrated sludge, clarified wastewater, oil purification and recovery; the third stage: concentrated sludge → two- and three-phase centrifuge sludge Dehydration and drying

prepare for exam

Oil transfer and residual material recovery and purification → Once the owner’s oil inspection report is qualified, the receiving operation will begin. ;Wastewater discharge treatment → Clarified wastewater SS below 1000ppm complies with Formosa Plastics regulations and shall be discharged and received according to the instructions of the owner. ; Sludge cake dehydration and drying → Formosa Plastics regulations require acceptance standards, and the owner indicates the location for storage.

Introduction to the principle of multi-stage vortex flow

Six-stage cyclone

VOC condensing unit functions

Achievements

R&D

Equipment rental

Patent