Gasifier

Gasifier introduction

A waste treatment furnace and processing equipment having the waste treatment furnace are used to solve the problems that conventional waste treatment furnaces easily cause pollution and equipment are easily damaged.

The treatment furnace system includes: a furnace body, which is surrounded by a shell to form a treatment space, the furnace body has an activated carbon layer, the activated carbon layer is located in the treatment space, an exhaust pipe is connected to the activated carbon layer; and a microwave The emission module is located on the activated carbon layer. The treatment equipment includes: the waste treatment furnace; a heat exchange system with a first heat exchange module connected to the exhaust pipe of the furnace body, a liquid storage member connected to the first heat exchange module; and a purification The module has an air inlet and an exhaust port. The air inlet is connected to the first heat exchange module. There is a spray area between the air inlet and the exhaust port.

Gasifier introduction

Fengjia University-High-value electronic applications of bamboo charcoal and its derivatives

Donghua University-SRF test burning verification experiment

In the past, when gasifiers were used to process agricultural waste, biomass, and organic materials, their efficiency could be determined by operating the gasifier under normal design. However, when transferring general household waste or businesses mixing hazardous materials. The temperature of the gasifier is different due to the different caloric levels of the types of biomass combustion, causing the redox temperature to be unable to stably maintain high-temperature reactions, resulting in many unburned carbon layers that cannot be fully cracked in the redox layer.

Gasifier developed by I-san Company

The improvement method is as follows

Add one or more microwave devices outside the furnace in the reduction layer area

Microwaves can penetrate inorganic thermal insulation materials. Waveguide microwave radiation is input into the carbon layer in the furnace to add energy. The carbon layer has active properties in the high-temperature anaerobic furnace. It can absorb microwave energy and increase it to the cracking temperature, reducing the carbon layer microwave Add energy to completely react the synthesis gas.

Unburned carbon layer redox high temperature conditions

Biomass-burning waste can be completely cracked. The microwave device of this gasification furnace can effectively control the operation of the syngas produced by pyrolysis, and the practical application technology of the gasification furnace has been improved.

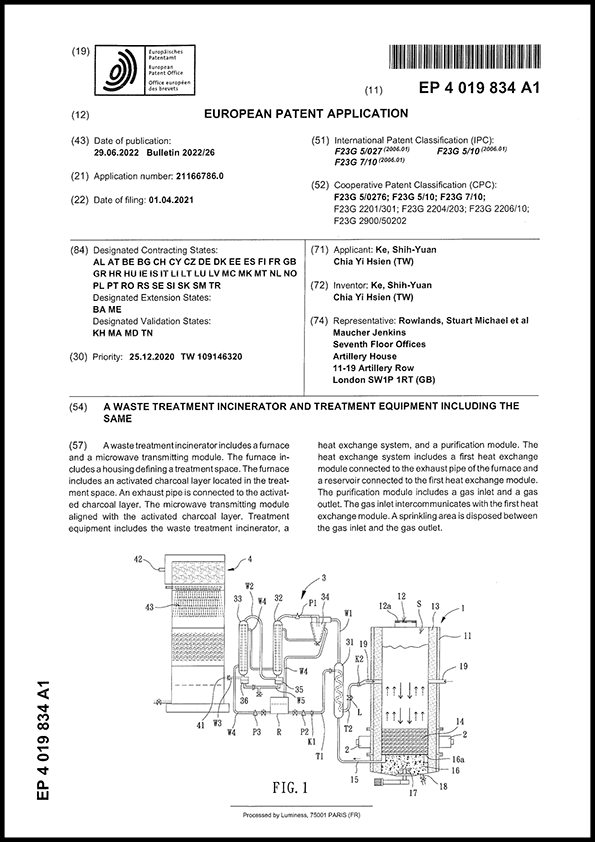

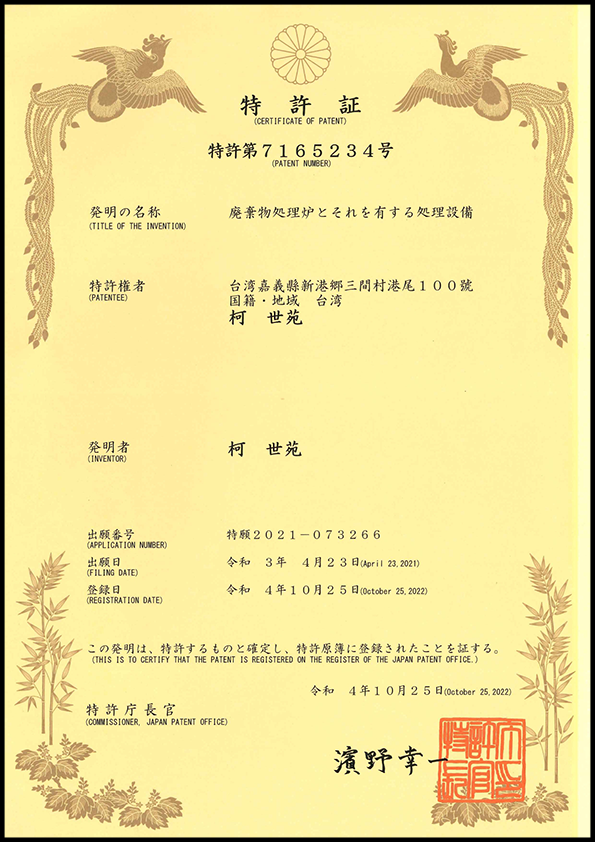

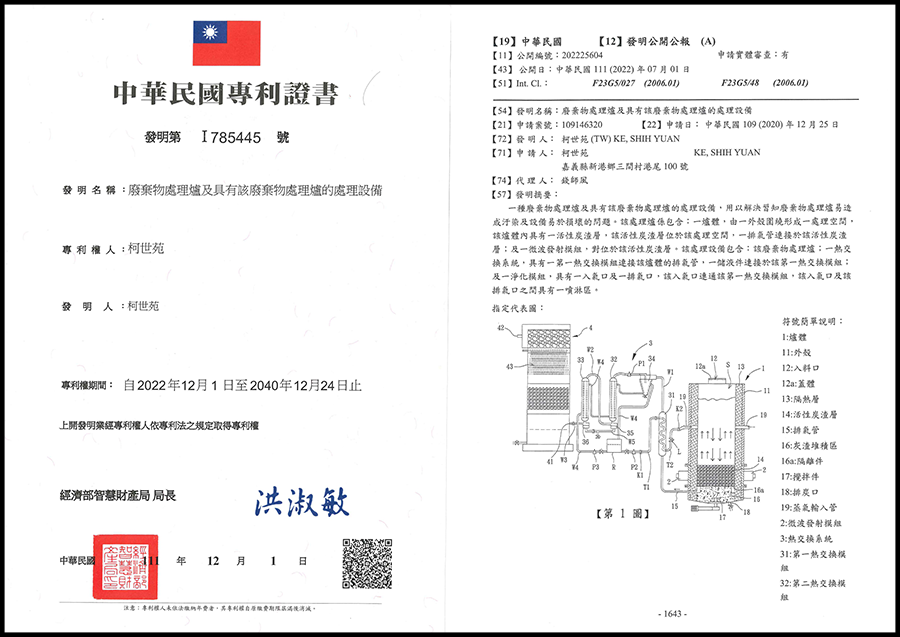

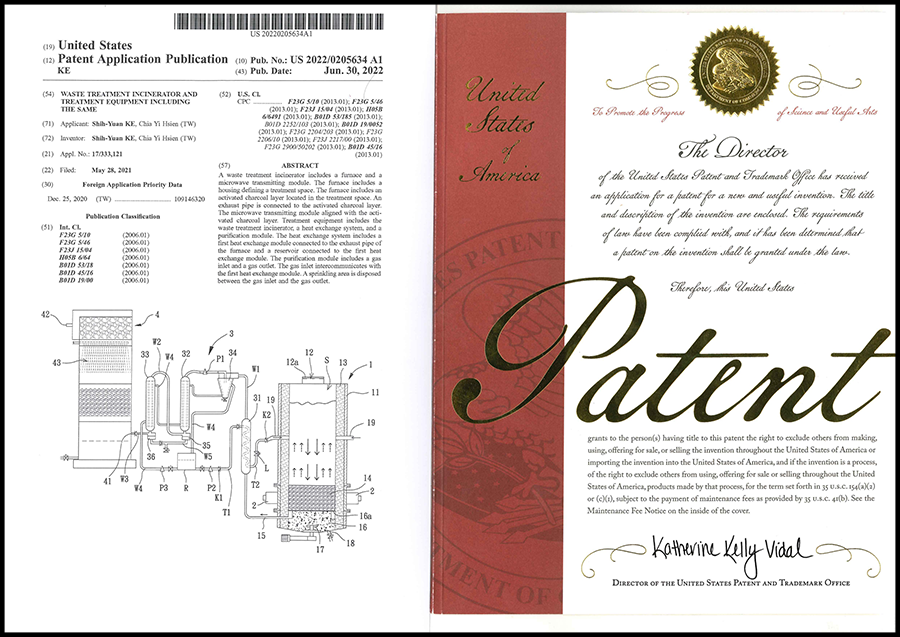

Patent