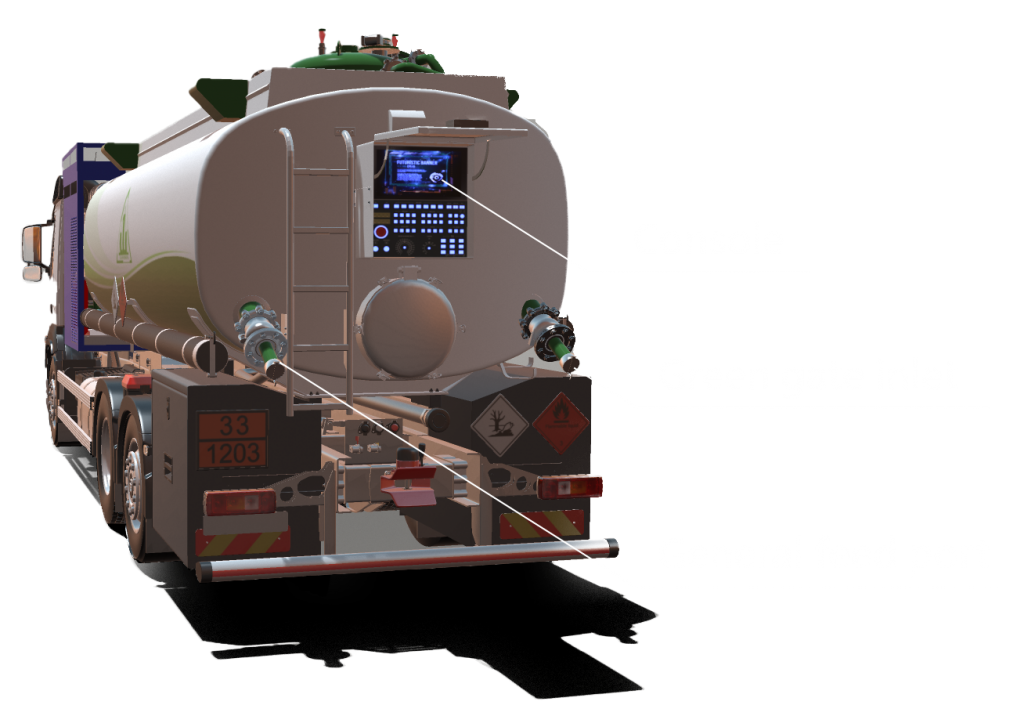

VOC Truck

Traditional vacuum pumping tank truck

Extract

The vacuum tank gate valve connects the pipeline to the contaminated area to extract any contaminated wastewater and chemical harmful substances.

Remove explosive hazardous chemicals

Pollution prevention and control work in the petroleum, chemical, and steel manufacturing industries includes cleaning of production process storage tanks, wastewater treatment systems and other pollution removal work. Especially in confined space and oxygen-deficient sealed high-risk places, it is very important to remove harmful substances from explosive chemical solvents.

Reduce the risk of contamination caused by personnel on site

When vacuum pumping and storage pollutes the regional environment, the negative pressure reduces the risk of pollution caused by human body exposure when personnel clean up harmful substances on site. Vacuum pumping tank trucks are very suitable for environmental pollution cleanup projects.

Environmental awareness of global warming is rising, and pollution prevention and control is urgent.

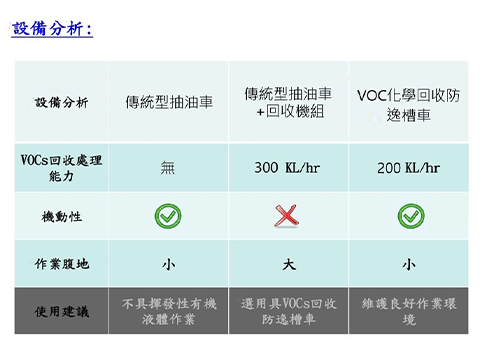

I-san Chemical Pumping Storage VOCs Recovery Anti-Escape Tank Truck

Design of pumped storage in normal pressure storage tanks

The new type retains the old design of the vacuum storage tank, and uses the pumping storage tank and extraction vacuum equipment. It solves the problem of VOC volatilization and emission pollution caused by the negative pressure in the storage tank during the extraction operation of the old storage tank. The new type adopts a pump-storage design of a normal pressure storage tank. During the pumping and storage pollution operation, the pollutants in the storage tank are sealed at normal pressure and there is no concern about VOC volatilization and pollution. The new type of negative pressure isolation pumps and stores the pollution area, greatly reducing the volume by more than 20 times, and can reduce VOC pollution by more than 95%.

Single-axis air-tight conveying pumping and storage equipment

When the pumped storage vehicle is in standby operation, the single-axis switching design function is designed to avoid any VOC and odor emission problems caused by the environment. The new single-axis air-to-air conveying pumping and storage equipment reduces the power output of the vacuum pumping equipment. Due to the reduced pumping and storage volume, the vacuum pumping and storage power output effectively reduces energy consumption by more than 80% during pollution extraction operations under the same conditions. The new type of extraction operation is designed for normal pressure. The structural strength of the storage tank can reduce the required standards and greatly improve the safety of use in the storage tank. The design of the normal pressure storage tank simplifies the structural manufacturing and can save a lot of costs.

Single-axis air-to-air conveying design

The new single-axis air-to-air conveying design improves the VOC emission problem of traditional pumped storage trucks in the exhaust gas, significantly reduces pollution emissions, and effectively controls fire safety hazards and environmental health pollution prevention and control. The new single-axis air-to-air conveying and pumping storage equipment is simple to operate, durable in structure, and low in maintenance costs. The working environment of the pumped storage truck is exposed to chemical solvents and storage tank equipment in strong acid and alkali places. The shaft seal can prevent the generation of static sparks. It can withstand strong acid and alkali anti-corrosion materials 316L and Teflon materials. It has an explosion-proof power design function and uses air to drive the gate valve. Control, automatic function abnormal emission safety protection. The new single-axis air-to-air conveying design has imported upper and lower gravity flow conveying functions and is easy to control. When equipment malfunction occurs, emptying and discharging materials from top to bottom can quickly repair and maintain the equipment without affecting the functional operation of other equipment.

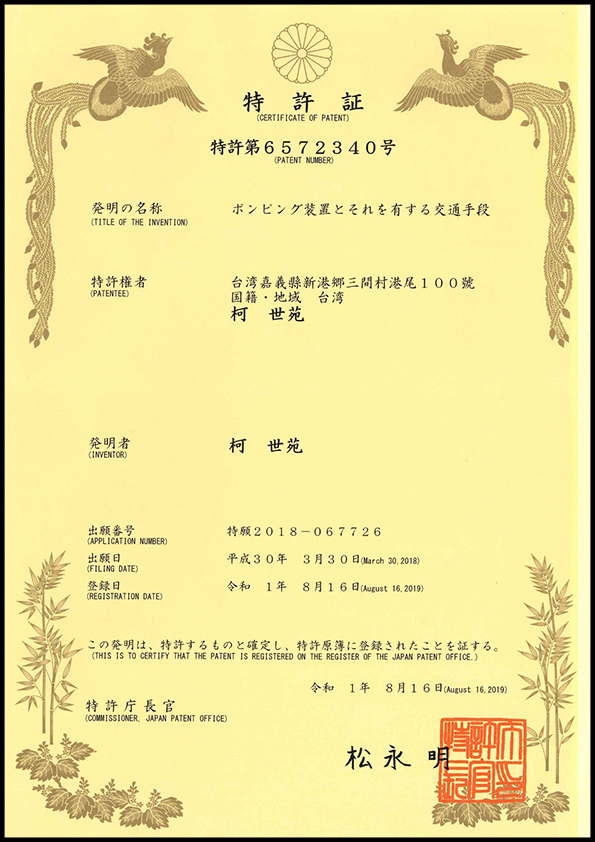

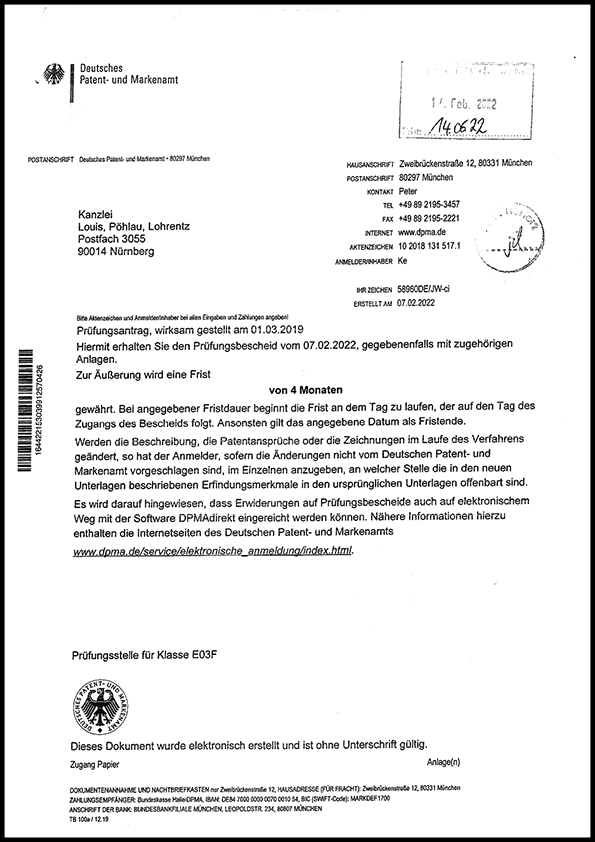

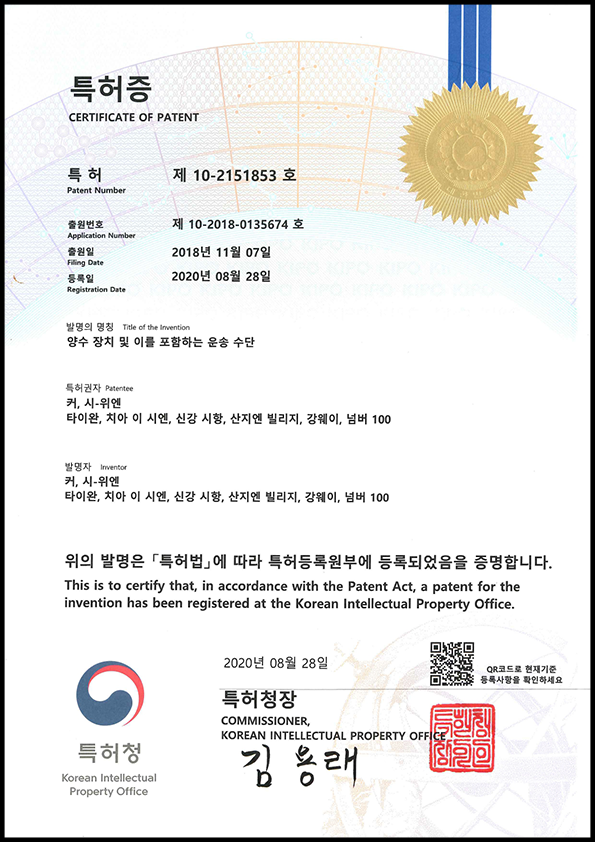

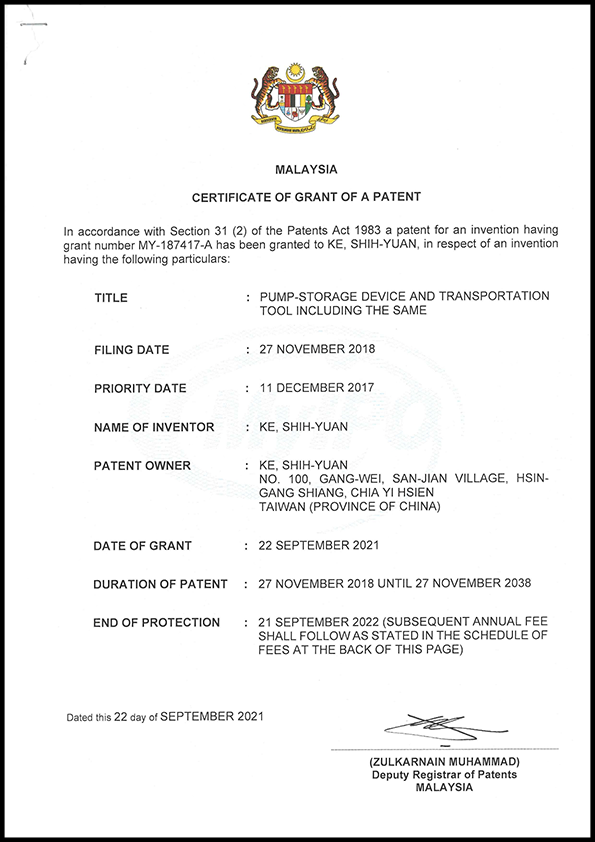

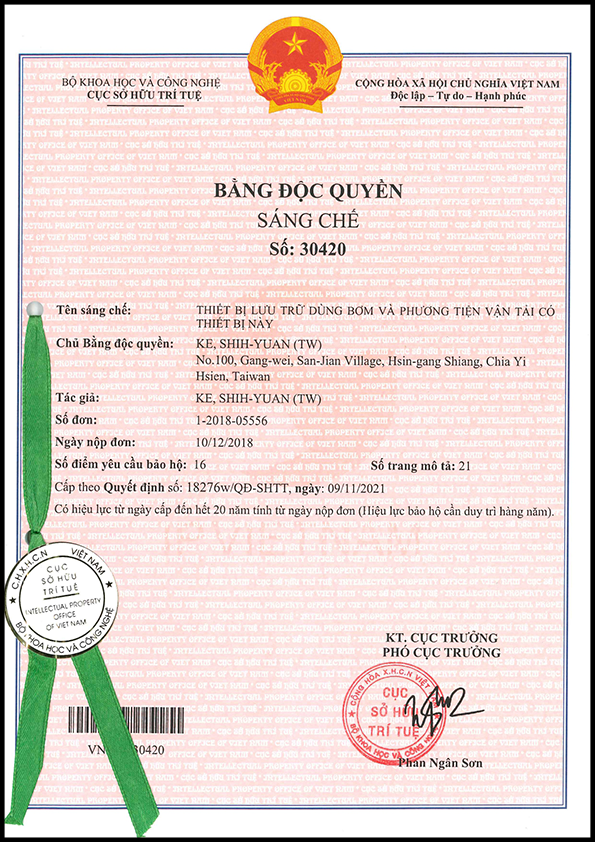

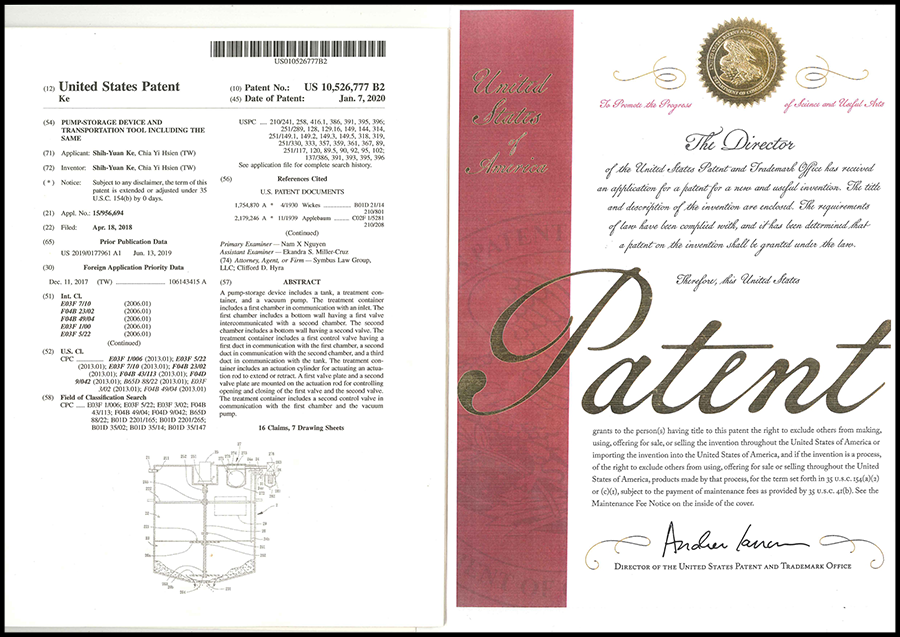

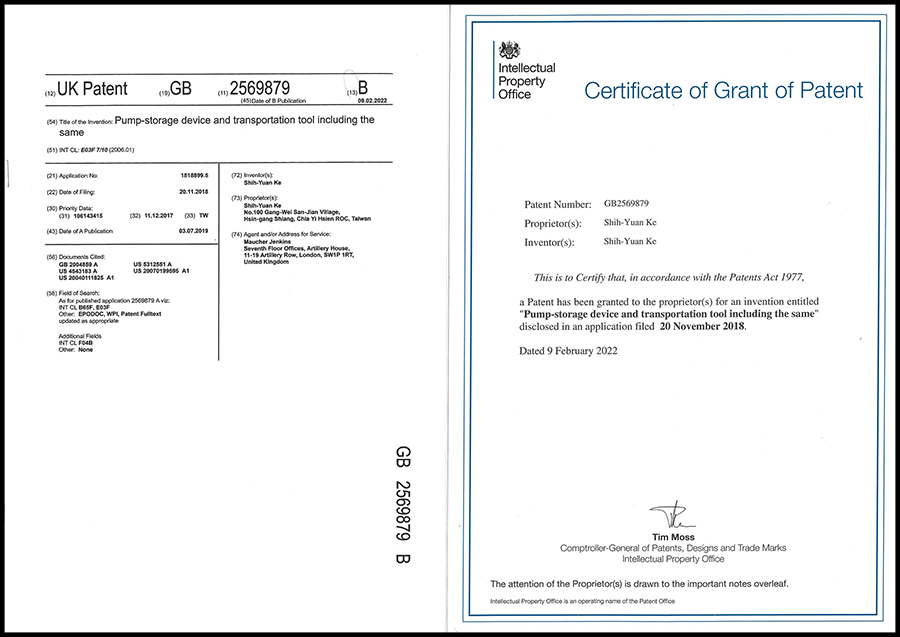

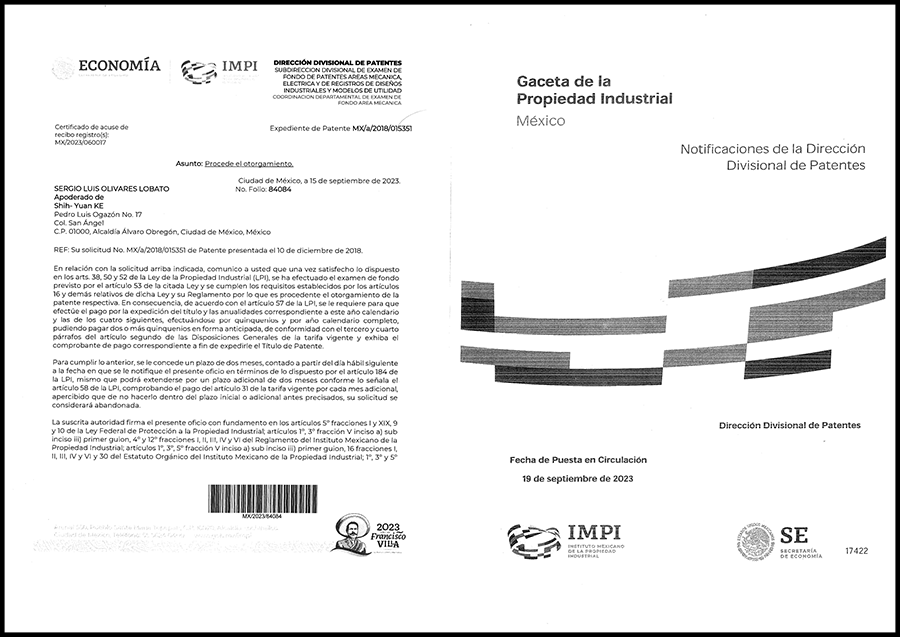

Patent